or Call Us at 1-800-776-2228

or Call Us at 1-800-776-2228

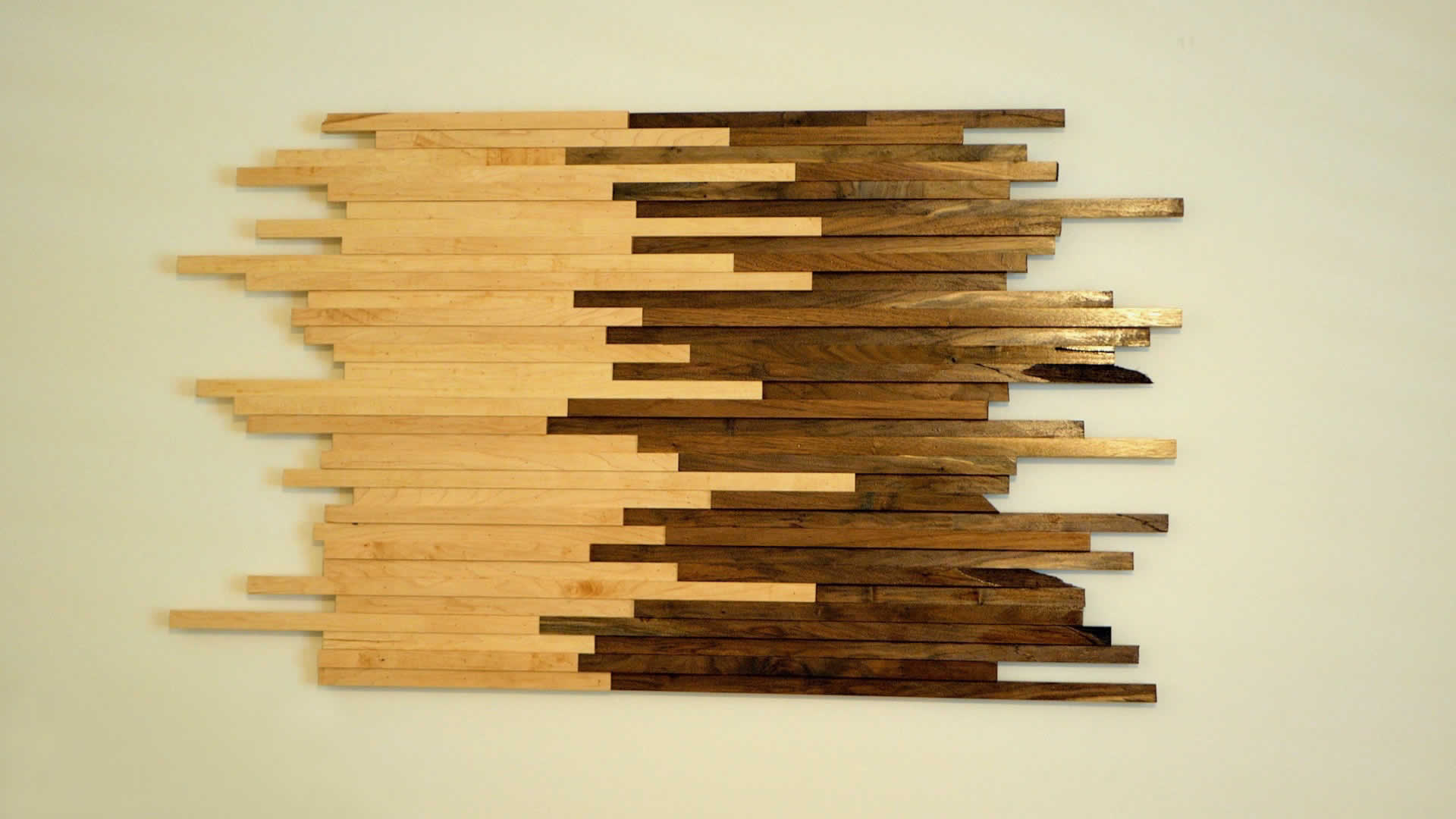

I'll show you how to build a piece of scrap wood wall art using maple and walnut scraps. This simple wooden art project adds a ton of style to any space, and you only need a table saw and Arrow's PT23G Pin Nailer to make it.

(Optional) The lumber I used on this build was a pile of rough maple and walnut scraps I had been hanging on to, and since the wood was rough, I needed to mill the pieces. This means I needed to flatten the two faces on the planer and square up one edge on the jointer so the pieces could be safely ripped on the table saw.

Make sure to mill all of your pieces to the same thickness on this step. The thickness here will be the width on the final piece of art, since we’ll be rotating the strips we rip in the next step before attaching them to the plywood.

(Optional) The lumber I used on this build was a pile of rough maple and walnut scraps I had been hanging on to, and since the wood was rough, I needed to mill the pieces. This means I needed to flatten the two faces on the planer and square up one edge on the jointer so the pieces could be safely ripped on the table saw.

Make sure to mill all of your pieces to the same thickness on this step. The thickness here will be the width on the final piece of art, since we’ll be rotating the strips we rip in the next step before attaching them to the plywood.

I started by ripping my pieces of hard maple into two even strips on the table saw, about 5/8″ wide. Again, the width of the strips here will be the depth of the strips on the final piece, and we want the depth of these pieces to be staggered. This gives the piece a much more interesting look than if all of the pieces were the same depth.

After ripping about half of the pieces into 5/8″ strips, I moved the fence over 1/4″ and kept ripping strips until I ran out of wood. I ended up with three different widths of strips, and this made for an awesome looking piece of art.

I started by ripping my pieces of hard maple into two even strips on the table saw, about 5/8″ wide. Again, the width of the strips here will be the depth of the strips on the final piece, and we want the depth of these pieces to be staggered. This gives the piece a much more interesting look than if all of the pieces were the same depth.

After ripping about half of the pieces into 5/8″ strips, I moved the fence over 1/4″ and kept ripping strips until I ran out of wood. I ended up with three different widths of strips, and this made for an awesome looking piece of art.

I used a scrap piece of 3/4″ plywood for this build, but 1/2″ plywood would work fine as well. I first cut my piece to about 28″ square, then tilted the table saw blade to 45 degrees and cut a bevel on all of the edges of the board. Cutting this bevel makes the edge of the plywood disappear when you’re looking at the artwork from the side.

I used a scrap piece of 3/4″ plywood for this build, but 1/2″ plywood would work fine as well. I first cut my piece to about 28″ square, then tilted the table saw blade to 45 degrees and cut a bevel on all of the edges of the board. Cutting this bevel makes the edge of the plywood disappear when you’re looking at the artwork from the side.

My buddy Grant, who was hanging out in the shop with me, cut a square end on each of the strips at the miter saw while I worked on the plywood. The strips need to meet up cleanly in the middle of the art, hence the need for one square end. We left the opposite ends of the strips rough and jagged and I really think this added a lot to the look of the piece.

My buddy Grant, who was hanging out in the shop with me, cut a square end on each of the strips at the miter saw while I worked on the plywood. The strips need to meet up cleanly in the middle of the art, hence the need for one square end. We left the opposite ends of the strips rough and jagged and I really think this added a lot to the look of the piece.

With the strips cut to size, I started arranging them on the plywood. I made sure to alternate the different sized strips, both depth and length, to give the piece a random appearance. Once I had the pieces arranged in a way that I liked, I used Arrow’s PT23G Pin Nailer to fasten the strips to the plywood. I just kept adding strips until I filled up the plywood.

With the strips cut to size, I started arranging them on the plywood. I made sure to alternate the different sized strips, both depth and length, to give the piece a random appearance. Once I had the pieces arranged in a way that I liked, I used Arrow’s PT23G Pin Nailer to fasten the strips to the plywood. I just kept adding strips until I filled up the plywood.

I lightly sanded the pieces before finishing and then applied the finish with a foam brush. I applied three coats in total.

I lightly sanded the pieces before finishing and then applied the finish with a foam brush. I applied three coats in total.

To hang the artwork, I used metal hardware that’s similar to a French cleat. You attach one half to the artwork and then attach the other half to the wall. This cleat supports up to 200 pounds, which is good since this artwork ended up being really heavy. I made sure the cleat was level and attached the cleats to each other, and the artwork was done!

To hang the artwork, I used metal hardware that’s similar to a French cleat. You attach one half to the artwork and then attach the other half to the wall. This cleat supports up to 200 pounds, which is good since this artwork ended up being really heavy. I made sure the cleat was level and attached the cleats to each other, and the artwork was done!

I'm really happy with the way this piece turned out. It was a simple build, I don't think it took me more than about 3 hours, but I love the result. It looks great in my den and is really a focal point of the room. Hope you enjoyed the project!

Get Arrow tips, tricks, projects and promos in your inbox!

Hey there! We’ve updated our Privacy and Cookie Policies at the request of some of our friends in Europe. Click Accept to let us know you’re okay with the updates. Thanks!

View Cookie Policy Accept